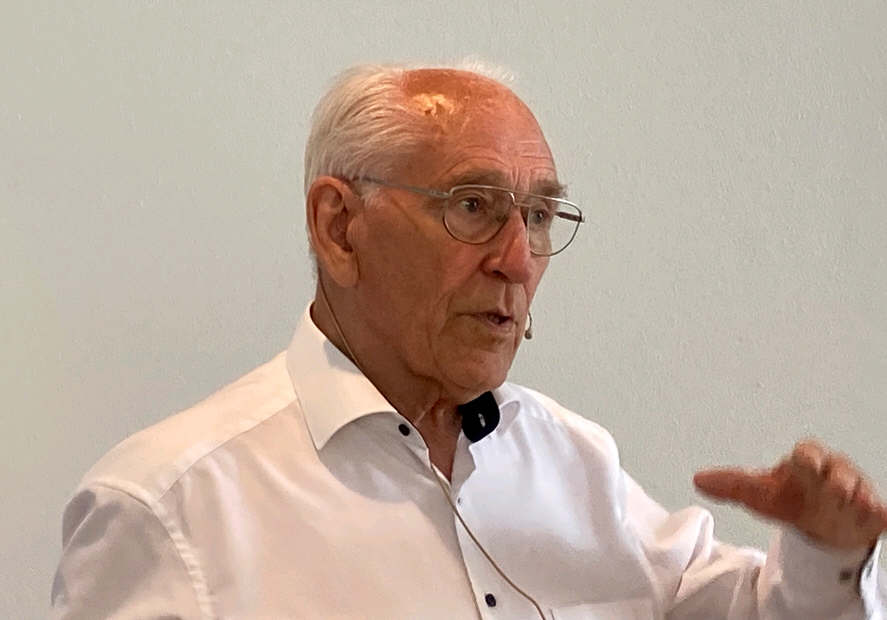

The world’s largest vertical solar project, with a capacity of 17.4 MWp, went into operation at Frankfurt Airport in 2025. AquaSoli supplied the foundation design.

Vertical photovoltaic system at Frankfurt Airport, mounted on foundations designed by AquaSoli (photo: FraPort)

Successful Flagship PV Project at Frankfurt Airport

37,000 vertical solar modules were installed along a 2,800-meter stretch of the airport’s west runway. The new system has a peak output of 17.4 megawatts (MWp) and will supply up to 17.4 million kWh of green electricity annually. AquaSoli carried out the foundation engineering based on pile load tests (POT) and created the load-bearing basis for this major project. The high horizontal loads caused by wind were decisive for the geotechnical design of the supporting structure.

The new PV system is located directly on the west runway of Frankfurt Airport, which is well known throughout Germany (photo: FraPort).

This example impressively demonstrates how AquaSoli is contributing to the energy transition—including in the transportation sector—through its geotechnical expertise and engineering know-how, literally laying the groundwork and foundations for this pioneering PV milestone.

Airport operator Fraport is proud of the new project, which contributes to energy supply and sustainability at the site: With the commissioning of the innovative photovoltaic system on the west runway – consisting of 37,000 vertically arranged modules – up to 17.4 million kilowatt hours of electricity will be produced here annually for the group companies based at Frankfurt Airport. The solar energy generated will primarily be used to power the terminal air conditioning system and supply the growing fleet of electric vehicles.

Together with Kaweh Mansoori, Hessian Minister for Economics, Energy, Transport, Housing, and Rural Areas, Fraport CEO Dr. Stefan Schulte flipped the switch in a transformer station, symbolically putting the entire system into operation. “By 2045 at the latest, Fraport will operate Frankfurt Airport with net-zero status, i.e., greenhouse gas-neutral and CO2-free. The key lever for this is clearly defined: the electricity mix at our home location will consist largely of renewable energies. Today, we have come a good deal closer to this ambitious goal,” said Schulte, emphasizing the central importance of the project in the Fraport Group’s decarbonization strategy.

“Here at the airport, we rely on green electricity from solar power and have also been incorporating smaller wind power quotas into our electricity mix since 2021. As a result, we already achieve a green electricity share of around 90 percent today.” FraPorts Power Purchase Agreement will come into effect in mid-2026. “This means that we have secured 85 megawatts of green power for 2021 and will be able to meet 100 percent of our Group’s energy needs in Frankfurt from renewable resources,” he announced.

Commitment to innovation and progress in Hesse

“Frankfurt Airport is Hesse’s gateway to the world and an important and valuable employer in the region. Today’s commissioning is not only a milestone for the airport’s climate-friendly energy supply, it is also a commitment to innovation and progress in Hesse. As the main shareholder of Fraport AG, the state of Hesse clearly supports the Fraport Group and its sustainability strategy,” Mansoori said.

“Today’s commissioning is a milestone toward our Net Zero climate protection goal. The widespread attention that this innovative plant has attracted around the world also confirms our approach of boldly forging ahead and breaking new ground to lead global air traffic safely into a sustainable future,” Schulte added.

Maintenance and care from our own hands

In 2022, Fraport tested the new technology in a small demonstration plant, tried out maintenance and green space care, and found it to be good. Further expansion began in spring 2024. The construction intervals were based on the breeding and nesting season, taking into account the diverse life in the airport’s biodiverse green spaces. The vertical design of the system ensures that the vegetation below can continue to thrive, as the modules do not block sunlight or precipitation. “These advantages make PV fences attractive not only for our airport, but also for public spaces,” explains Schulte. “Numerous representatives of regional politics, urban planners, and our colleagues from the international airport industry have been able to see this for themselves in recent months. At Frankfurt Airport, there are a variety of expansion options within our rail system that we are already considering,” he announces.

Stability thanks to a combined solution

The new system is not only space-saving and environmentally friendly, but also perfectly complements existing conventional PV systems at the airport. These can be found on roof surfaces and are also being installed on the parking garage and main building of the new Terminal 3. Conventional panels are mounted at an angle and achieve their peak performance at midday, while the collectors on the fence are aligned in an east-west direction and therefore capture sunlight in the morning and afternoon hours. The combination of both technologies thus achieves a stable solar power supply throughout the day.

Group-wide climate protection target: net zero

Further information on the decarbonization of the Fraport Group and the power supply for Frankfurt Airport can be found in the Climate Protection Press Kit. The Fraport Group is committed to achieving net zero status at all fully consolidated locations within Scopes 1 and 2 by 2045 at the latest. This no longer only includes CO2, but all climate-relevant greenhouse gases. Net zero means greenhouse gas neutrality.

(Sources of pictures and text: FraPort, Germany)

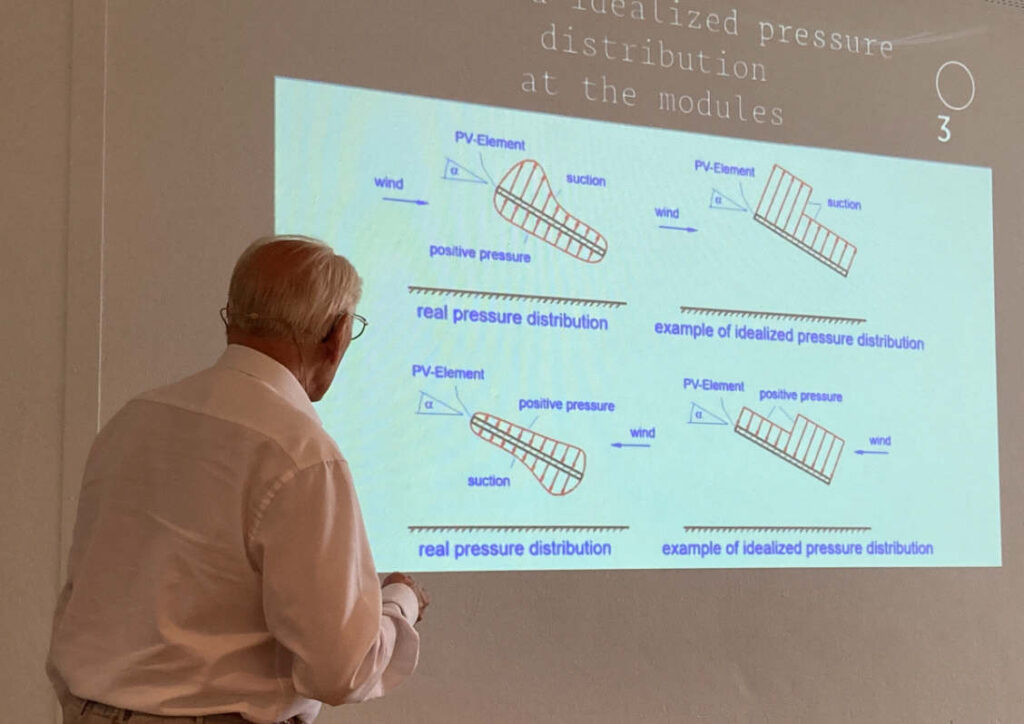

When designing foundations for solar farms, it is vital to consider both pile stiffness and soil stiffness; neither should be ignored. While pile stiffness is usually estimable with reasonable accuracy, soil stiffness is far more challenging to measure precisely. These uncertainties can impact both safety and reliability. That is why pile load tests (POT) are essential: they verify design assumptions, enhance safety, and help keep project costs in check.

When designing foundations for solar farms, it is vital to consider both pile stiffness and soil stiffness; neither should be ignored. While pile stiffness is usually estimable with reasonable accuracy, soil stiffness is far more challenging to measure precisely. These uncertainties can impact both safety and reliability. That is why pile load tests (POT) are essential: they verify design assumptions, enhance safety, and help keep project costs in check.

![Von AquaSoli beim Fundamentbau für das Kraftwerk Bilancia 1 auf Sizilien durchgeführte Eignungsprüfung und Qualitätssicherung [Foto: Frenell]](http://www.aquasoli.com/blog/wp-content/uploads/2022/12/Von-AquaSoli-beim-Fundamentbau-für-das-Kraftwerk-Bilancia-1-auf-Sizilien-durchgeführte-Eignungsprüfung-und-Qualitätssicherung-Foto-Frenell-20221124_110038-1024x485.jpg)

![Fundamentbau für das Kraftwerk Bilancia 1 auf Sizilien [Foto: Frenell]](http://www.aquasoli.com/blog/wp-content/uploads/2022/12/Fundamentbau-für-das-Kraftwerk-Bilancia-1-auf-Sizilien-Foto-Frenell-20221123_104156-1024x485.jpg)